Last time, we discussed a method whereby we could report on the efficiency of a crew by using indirect labor codes, and comparing the total labor on a production line to the total estimated labor for jobs produced on that line.

As we mentioned, we are unable to get a precise breakdown of labor hours by job, but we can get a fair estimate by using the weighted allocation that Epicor uses. When an employee clocks directly onto multiple operations at once, Epicor will allocate hours to each operation based on the weight of that operation's estimated hours. Let us make up an example:

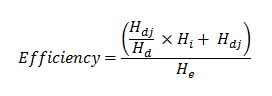

We want to estimate hours per job using this same weighting method. Remember that in Stage 1, we asked a team leader to clock directly onto each operation that the line is performing and each team member to clock onto an "indirect" code, selecting the line as his resource group. We propose to weight our total "indirect" hours proportionally to the team leader's actual direct hours. Our report will calculate efficiency like so:

This may not be as accurate as having each team member clock on and off of every operation, but from these data, we can get an accurate overall gross margin, and a fair estimate of profitability and efficiency per job.